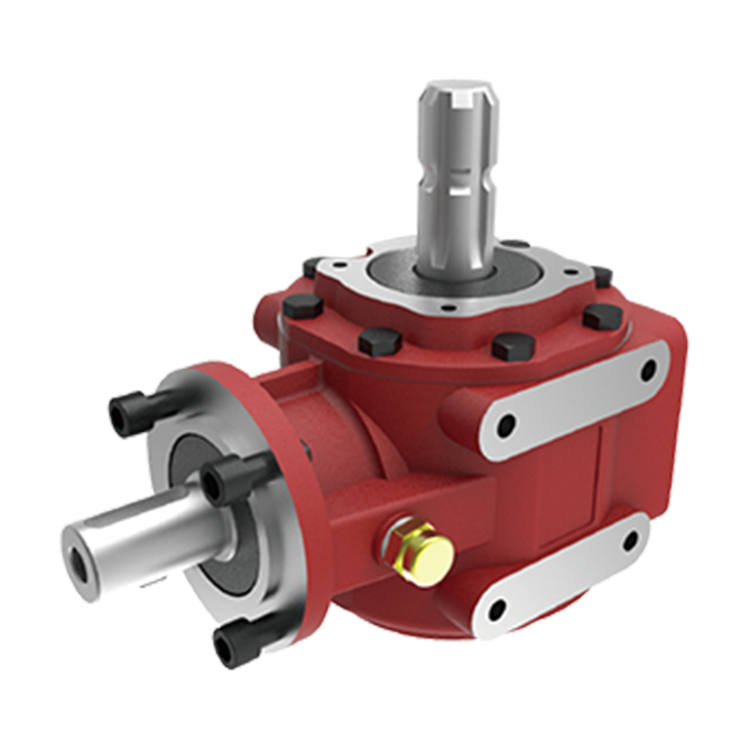

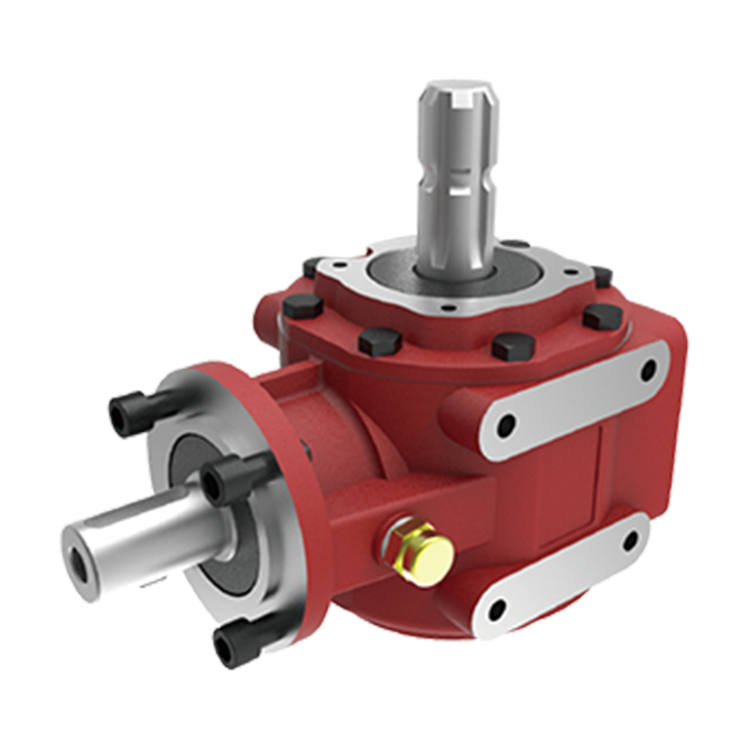

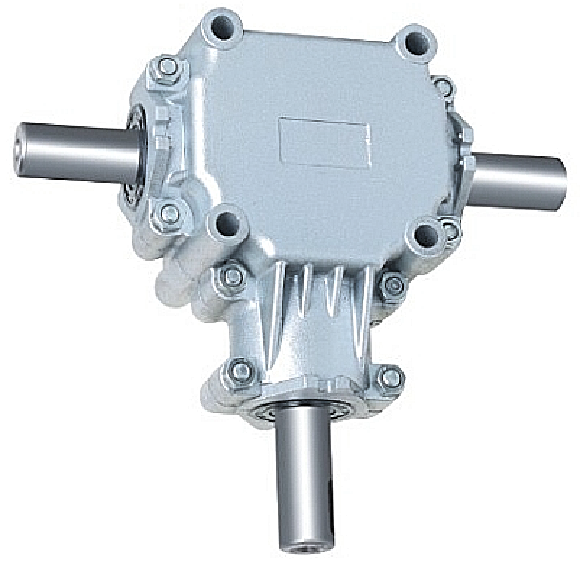

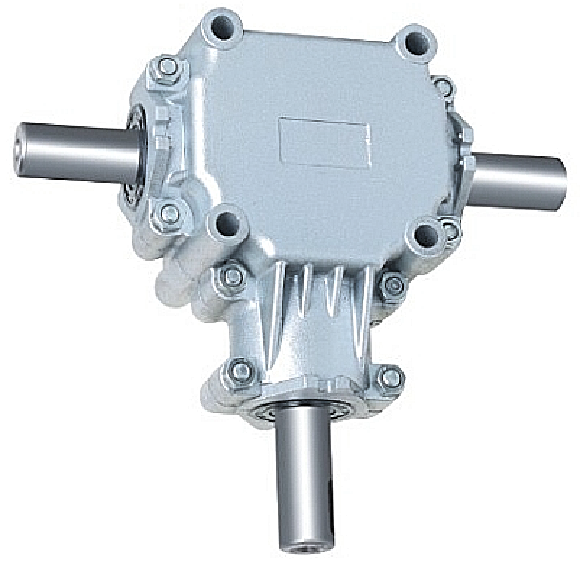

Product Description

Product Description

|

Item No.: |

B 0571 , Cast Iron Gearbox |

|

Ratio and Shaft: |

OEM acceptable |

|

Key word |

Agricultural Machinery Gearbox |

Company Profile

HangZhou Hengni Machinery Co., Ltd. was founded in 2571 by Ms. Iris and her 2 partners (Mr. Tian and Mr. Yang) in HangZhou City, ZHangZhoug Province, China. All 3 founders are average senior engineers. Due to business expansion, the company moved to its current location in Xihu (West Lake) Dis. Industrial Zone (HangZhou, ZHangZhoug Province, China) in 2014.

We specialize in a full line of spiral bevel gearboxes, spur gearboxes, spur gearboxes, drive shafts, sheet metal, hydraulic cylinders, motors, tires, worm gear reducers, and worm operators, providing solutions for agricultural machinery manufacturers and distributors worldwide. All products can be customized on request.

We have a complete quality management system and sales and service network to provide our customers with quality products and satisfactory services. Our products are sold to 36 countries and regions around the world and our main market is the European market.

Certifications

Packaging & Shipping

Main Products

FAQ

Q: Are you trading company or manufacturer ?

A: We are exactly a factory.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance, balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | 135 Degree |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Advantages and disadvantages of worm gear reducer gearbox

If you are looking for a worm gear reducer gearbox, you have come to the right place. This article will cover the pros and cons of worm gear reducer gearboxes and discuss the different types available. You will learn about multi-head worm gear reducer gearboxes, hollow shaft worm gear reducer gearboxes as well as hypoid gear sets and motors.

Hollow shaft worm gear reducer gearbox

Hollow shaft worm gear reducer gearboxes are used to connect two or more rotating parts. They are available in single-axis and dual-axis versions and can be connected to various motor types. They can also have different ratios. The ratios of these gear reducer gearboxes depend on the quality of the bearings and assembly process.

Hollow shaft worm gear reducer gearboxes are made of bronze worm gears and cast iron hubs. The gears are lubricated with synthetic oil. They are lightweight and durable. They can be installed in various engine housings. Additionally, these gear reducer gearboxes are available in a variety of sizes. The range includes 31.5, 40, 50, 63, and 75mm models. Other sizes are available upon request.

In addition to worm gear reducer gearboxes, there are also helical gear reducer gearboxes. These reducer gearboxes can achieve very low output speeds. They are also suitable for all-around installations. In addition, the advantage of a multi-stage reducer gearbox is that it is more efficient than a single-stage gear reducer gearbox. They also feature low noise, low vibration, and low energy consumption.

Hollow shaft worm gear reducer gearboxes are generally less expensive and last longer. They are also a suitable replacement for solid shaft gearboxes for machines that require high torque without compromising strength. Typical gear arrangements include worm, spur, helical and bevel gears. Gear ratio is the ratio of input torque to output torque.

Multi-head worm gear reducer gearbox

The multi-head worm gear reducer gearbox is used to reduce the speed of the machine. It uses friction to hold the worm in place while transmitting power. These gears can also be called ground worms and hardened worm gears. They are useful in conveying systems and most engineering applications.

Multiple worm reducer gearboxes have a large number of gear ratios. These gear designs have a central cross-section that forms the front and rear boundaries of the worm gear. This design is a better choice than other worm gears because it is less prone to wear and can be used with a variety of motors and other electronics.

Adjustable multi-head worm gear reducer gearbox to reduce axial play. Usually, the backlash on the left and right sides of the worm is the same. However, if you need less backlash, you can buy a double lead worm gear. This design is ideal for precision applications requiring small clearances. The lead of the opposing teeth of the double worm gear is different from the right side, so the backlash can be adjusted without adjusting the center distance between the worm gears.

Worm gear reducer gearboxes are available from a variety of manufacturers. Many gear manufacturers stock these gears. Since the gear ratios are standardized, there is no need to adjust the height, diameter, or length of the shaft. Worm gears have fewer moving parts, which means they require less maintenance.

Hypoid Gear Set

Worm gears are the most common type of gear. While these gears are great for high-to-low ratios, hypoid gear sets are much more efficient in all ratios. This difference is due to higher torque density, better geometry and materials, and the way hypoid gears transmit force differently than worm gears.

Hypoid gear sets have curved helical teeth. This results in smooth gear meshing and little noise. This is because the hypoid gears start to slowly contact each other, but the contact progresses smoothly from tooth to tooth. This reduces friction and wears, thereby increasing the efficiency of the machine.

The main advantages of hypoid gears over worm gears are higher torque capacity and lower noise levels. Although their upfront cost may be higher, hypoid gears are more efficient than worm gears. They are able to handle higher initial inertia loads and can deliver more torque with a smaller motor. This saves money in the long run.

Another advantage of hypoid gears is the lower operating temperature. They also do not require oil lubrication or ventilation holes, reducing maintenance requirements. The hypoid gear set is maintenance-free, and the grease on the hypoid gear set lasts for decades.

Hypoid gear motor

A hypoid gear motor is a good choice for a worm gear reducer gearbox as it allows for a smaller motor and more efficient energy transfer. In fact, a 1 hp motor driving a hypoid reducer gearbox can provide the same output as a 1/2 hp motor driving a worm reducer gearbox. A study by Agknx compared two gear reduction methods and determined that a hypoid gear motor produces more torque and power than a worm reducer gearbox when using a fixed reduction ratio of 60:1. The study also showed that the 1/2 HP hypoid gear motor is more energy efficient and reduces electricity bills.

Worm reducer gearboxes run hotter than hypoid gears, and the added heat can shorten their lifespan. This can cause components to wear out faster, and the motor may require more frequent oil changes. In addition, hypoid gear motors are more expensive to manufacture.

Compared to worm gears, hypoid gears offer higher efficiency and lower operating noise. However, they require additional processing techniques. They are made of bronze, a softer metal capable of absorbing heavy shock loads. Worm drives require work hardening and are less durable. Operating noise is reduced by up to 30%, and hypoid gears are less prone to breakage than bevel gears.

Hypoid gear motors are prized for their efficiency and are used in applications requiring lower torque. A unique hypoid tooth profile reduces friction. In addition, hypoid gear motors are ideal for applications where space is limited. These geared motors are often used with pulleys and levers.

R series worm gear reducer gearbox

R series worm gear reducer gearboxes have a variety of characteristics that make them ideal for different applications. Its high rigidity cast iron housing and rigid side gears are designed for smooth drive and low noise. It also features high load capacity and long service life. Additionally, it can be assembled into many different configurations as required.

High efficiency, large output torque and good use efficiency. It comes in four basic models ranging from 0.12KW to 200KW. It can be matched with right angle bevel gearbox to provide large speed ratio and high torque. This combination is also suitable for low output and high torque.

AGKNX Electric Worm Gear reducer gearbox

AGKNX Electric worm gear reducer gearboxes are available with NEMA C-face mounting flanges for a variety of motors. These reducer gearboxes feature double lip oil seals, an aluminum alloy housing, and two bearings on the input and output shafts. These reducer gearboxes are rust-proof and have epoxy paint on the inside. They are available in a variety of ratios, from 7.5:1 to 100:1.

Worm reducer gearboxes are one of the most cost-effective and compact gears. These reducer gearboxes increase output torque while reducing input speed. AGKNX Electric’s worm gear reducer gearboxes are pre-installed with Mobil SHC634 Synthetic Gear Oil. These reducer gearboxes have an internal oil gallery guide to protect the shaft. They also have a one-piece cast iron housing.

AGKNX Electric Corporation is the leading independent distributor of electric motors in the United States. They have eight strategically located warehouses, enabling them to ship most orders on the same day. They offer motors of various sizes up to 20,000 hp. They also offer a variety of motor controls and variable speed drives.

editor by CX 2023-06-07

in Aurangabad India sales price shop near me near me shop factory supplier T Series Spiral Bevel Gearbox Reducer 90 Degree Gear Transmission Small Right Angle Spiral Bevel Gear Steering Gearbox manufacturer best Cost Custom Cheap wholesaler

we source chromed bar and tubes for hydualic and pheumatic cylinders. Each procedure, every area, every single operate in EPG is demanded to be carried out 1 step following another, carefully and cautiously, from substance choice, reformation to manufacturing add-ons, from parts warmth remedy to computerized assembly, from quality handle to merchandise inspection and tests and from order working to soon after income services. Possessing accrued treasured encounter in cooperating with international customers,

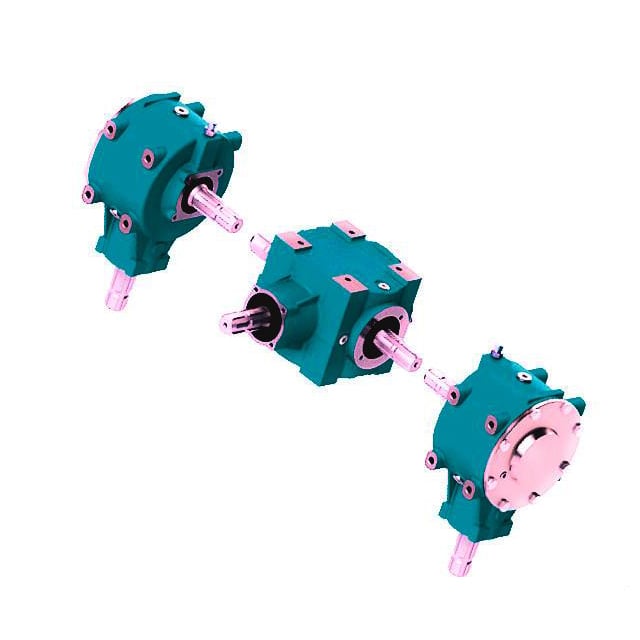

T sequence Spiral EPTl EPT EPT ninety degree EPT EPT Small RigEPT Angle Spiral EPTl Equipment Steering EPT

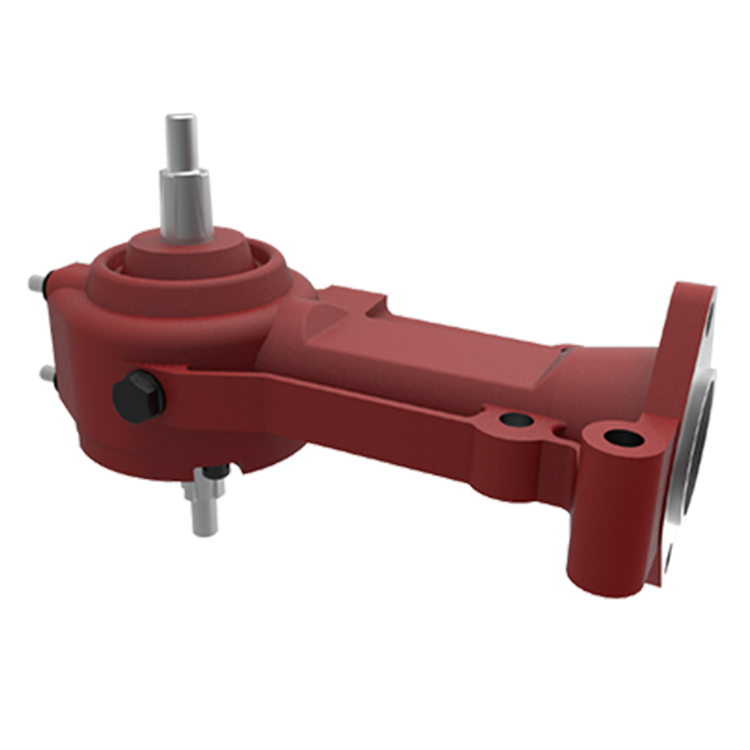

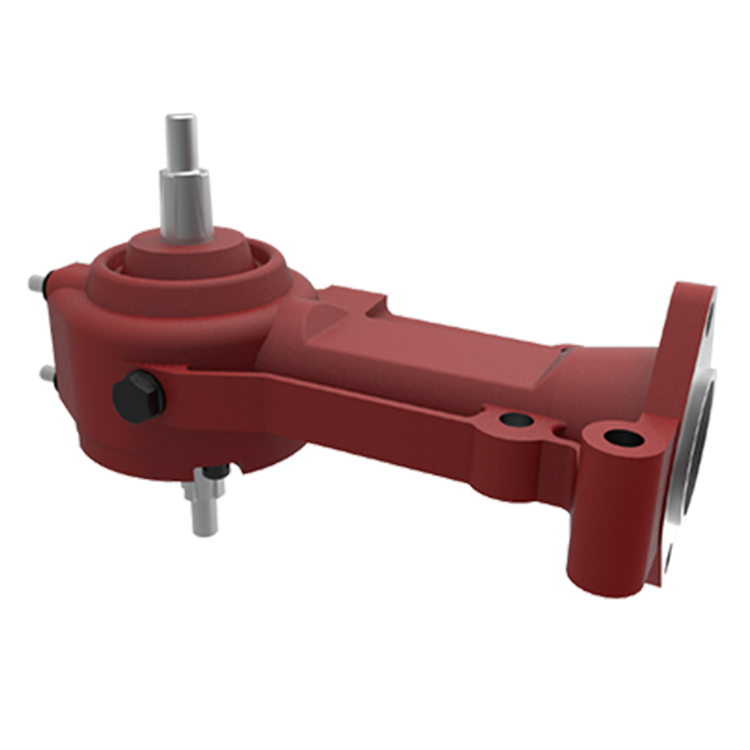

Product Description

Benefit:

-Self-locking ability

-Can be EPTn immediately by motor or other EPT or handbook

-Can be customized according user’s desire

-Compact configuration, little dimensions, lightweight

-Hassle-free set up, fleXiHu (West Lake) Dis.ble operation

-Large dependability and stability

-EPT support existence

-Much more relationship form and so on.

Screw jak is used to all fields for lifting or pulling, this kind of as EPT routine maintenance platform, EPT plate, EPTry, metallurgy, h2o conservancy, medical remedy, chemical sector, lifestyle and hygienist etc.

Requirements:

1.Tseries sprial EPTl EPT EPT with numerous types are stXiHu (West Lake) Dis.Hu (West Lake) Dis.rdized

2.all ratio of one:one,1.five:twelve:12.five:thirteen:fourteen:1and 5:one are true ones,

3.common performance is ninety eight%.

| Solution Name | T sequence Spiral EPTl EPT |

| model no. | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

| Ratio | one:one, one.five:one, two:1, 2.5:1,three:1,four:one,five:1 |

| EPT EPT | large quality synthetic diamond 50CrMnT |

| Gear Processing | Grinding complete by HOFLER Grinding EPTs, EPT grade : DIN four |

| spindle | large EPT metal alloy 40Cr piece |

| Sound Check | Bellow 65dB |

| Guarantee | one calendar year |

Company Data

EPT control

EPT

EPT Details: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd carton/Pallet/StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd wooden scenario

Supply Details : 15-thirty functioning daEPTupon payment

Our Certifications

Relevant Product

EPT Planetary EPT

| EPT Planetary EPT | Robotic RV EPT pace EPT |

| Customized made Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | UDL Series Variator |

| PYZ Collection Helical Tooth Shaft Mounted EPT | 8000 Series Cycloidal EPT |

| SLT Series Spiral EPTl EPT | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary EPT | SLH/SLB Series High EPT EPT |

| NMRV Sequence Worm EPT | BKM Collection Helical-hypoid EPT |

| SLRC Sequence Helical EPT | SLSMR Collection Shaft Mounted EPT |

| SLXG Sequence Shaft Mounted EPT | X/B Series Cycloidal EPT |

| SLR/SEPT/SLK/SLS Collection Helical EPT | AC/DC EPT |

FAQ

1.Payment Expression: TT, L/C

two.Delivery time: about thirty daEPTfrom EPT payment.

3.We settle for tailored goods as per your EPT necessity.

4.XiHu (West Lake) Dis.hu (West Lake) Dis.strains for the Choice:Normally we can choose 1 EPT which is appropriate for you with some informations from you,this kind of as ratio/motor speed/mounting dimension/ out torque and so on.

5.If the minimal orEPTamount is in surplus of $ten thousand, there are preferential.

Q1: What info must I explain to you to confirm the merchandise?

A:Model/Dimension, EPT Ratio, Shaft directions amp OrEPTquantity.

Q2: What can i do if I do not know which a single EPT?

A:Dont worry, Ship as much details as you can, our crew will aid you discover the rigEPT one you are hunting for.

Q3: What is your merchandise warranty interval?

A:We supply one particular yr guarantee because the vessel departure day still left EPT.

This fall: Are you buying and selling company or maker ?

A: We are factory.

Q5: How EPT is your shipping time?

A: EPTly it is 5-10 daEPTif the products are in inventory. or it is 15-20 daEPTif the merchandise are not in inventory, it is according to quantity.

Q6: Do you provide samples ? is it totally free or added ?

A: Sure, we could offer the sample for totally free charge but do not pay the EPT of freight.

Q7: What is your phrases of payment ?

A: Payment lt=1000USD, a hundred% EPT. Payment gt=1000USD, thirty% T/T EPT ,harmony prior to shippment.

If you have an additional query, pls really feel cost-free to get in touch with us as under:

Contact Us

in Marrakech Morocco sales price shop near me near me shop factory supplier Spiral-Bevel-Gearbox Spiral Bevel Gearboxes Small Bevel Gearbox Bevel Gearbox Right Angle Right Angle Spiral Bevel Gearbox manufacturer best Cost Custom Cheap wholesaler

Our merchandise assortment involves all types of helical gear, spur gear, bevel gear, equipment rack, worm gear, sprockets,chains, bearings. Because of to our sincerity in providing greatest service to our clientele, understanding of your needs and overriding perception of obligation toward filling ordering demands, Thanks to our vast item range and abundant activities in this industry,

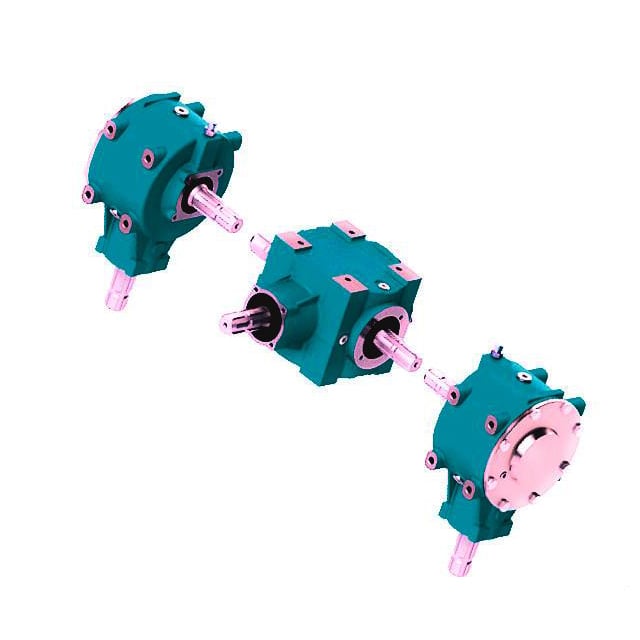

rigEPT angle EPT EPTl EPT motor spiral EPT motor four way spiral EPTl EPT 4 way EPT

Merchandise Description

Edge:

-Self-locking ability

-Can be EPTn directly by motor or other EPT or guide

-Can be customized in accordance user’s demand from customers

-Compact configuration, small size, light-weight

-Practical set up, fleXiHu (West Lake) Dis.ble procedure

-High trustworthiness and stability

-EPT provider existence

-Much more link sort and many others.

Screw jak is utilized to all fields for lifting or pulling, these kinds of as EPT servicing platform, EPT plate, EPTry, metallurgy, h2o conservancy, health-related treatment, chemical sector, tradition and hygienist and so forth.

Specs:

one.Tseries sprial EPTl EPT EPT with various sorts are stXiHu (West Lake) Dis.Hu (West Lake) Dis.rdized

2.all ratio of one:1,one.five:twelve:twelve.five:13:fourteen:1and five:one are true kinds,

three.average performance is 98%.

| Item Identify | T collection Spiral EPTl EPT |

| product no. | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25 |

| Ratio | 1:1, one.5:1, 2:one, 2.five:1,3:1,4:1,five:1 |

| EPT EPT | higher quality synthetic diamond 50CrMnT |

| Equipment Processing | Grinding finish by HOFLER Grinding EPTs, EPT quality : DIN four |

| spindle | high EPT steel alloy 40Cr piece |

| Noise Take a look at | Bellow 65dB |

| Warranty | 1 year |

Business Details

EPT control

EPT

EPT Particulars: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd carton/Pallet/StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd picket case

Shipping and delivery Particulars : 15-30 operating daEPTupon payment

Our Certifications

Related Product

EPT Planetary EPT

| EPT Planetary EPT | Robot RV EPT speed EPT |

| Custom made produced Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | UDL Collection Variator |

| PYZ Collection Helical Tooth Shaft Mounted EPT | 8000 Series Cycloidal EPT |

| SLT Series Spiral EPTl EPT | SLSWL Sequence Worm Screw Jack |

| SLP Series Planetary EPT | SLH/SLB Collection Large EPT EPT |

| NMRV Collection Worm EPT | BKM Collection Helical-hypoid EPT |

| SLRC Series Helical EPT | SLSMR Sequence Shaft Mounted EPT |

| SLXG Series Shaft Mounted EPT | X/B Series Cycloidal EPT |

| SLR/SEPT/SLK/SLS Sequence Helical EPT | AC/DC EPT |

FAQ

1.Payment Term: TT, L/C

two.Shipping and delivery time: about thirty daEPTfrom EPT payment.

three.We acknowledge custom-made merchandise as for every your EPT prerequisite.

four.XiHu (West Lake) Dis.hu (West Lake) Dis.strains for the Assortment:Typically we can pick one particular EPT which is appropriate for you with some informations from you,such as ratio/motor velocity/mounting dimension/ out torque and so forth.

5.If the bare minimum orEPTamount is in excessive of $ten thousand, there are preferential.

Q1: What information ought to I explain to you to verify the product?

A:Product/Measurement, EPT Ratio, Shaft instructions amp OrEPTquantity.

Q2: What can i do if I don’t know which one EPT?

A:Dont fear, Send out as considerably information as you can, our team will support you uncover the rigEPT a single you are looking for.

Q3: What is your solution guarantee interval?

A:We provide a single 12 months warranty since the vessel departure date still left EPT.

Q4: Are you buying and selling firm or maker ?

A: We are manufacturing unit.

Q5: How EPT is your shipping and delivery time?

A: EPTly it is 5-ten daEPTif the items are in inventory. or it is 15-20 daEPTif the goods are not in inventory, it is according to quantity.

Q6: Do you offer samples ? is it totally free or added ?

A: Sure, we could provide the sample for free demand but do not spend the EPT of freight.

Q7: What is your terms of payment ?

A: Payment lt=1000USD, one hundred% EPT. Payment gt=1000USD, thirty% T/T EPT ,stability before shippment.

If you have one more query, pls feel free to get in touch with us as below:

Contact Us

China manufacturer & factory supplier for Small in Fortaleza Brazil Right Angle Spiral Bevel Gearbox spiral bevel gearbox With high quality best price & service

Normal roller chain is obtainable with pitches from 1/2 to 3 inches. Chain numbers are identified by multiplying the pitch by eighty (a 1/2 inch pitch chain would be a No. forty chain). A hyphenated suffix suggests multiple strands.We examine every piece of bearing by ourselves prior to delivery.

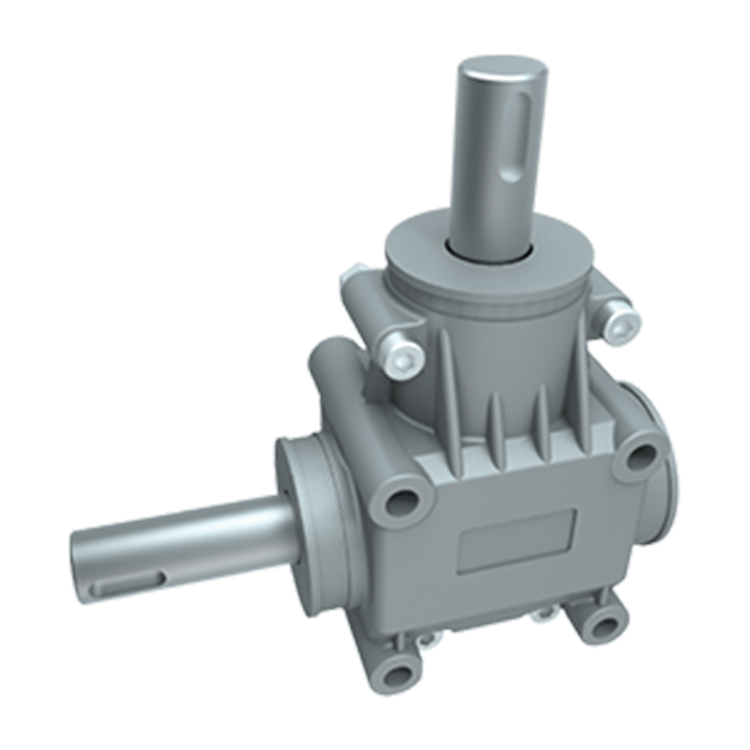

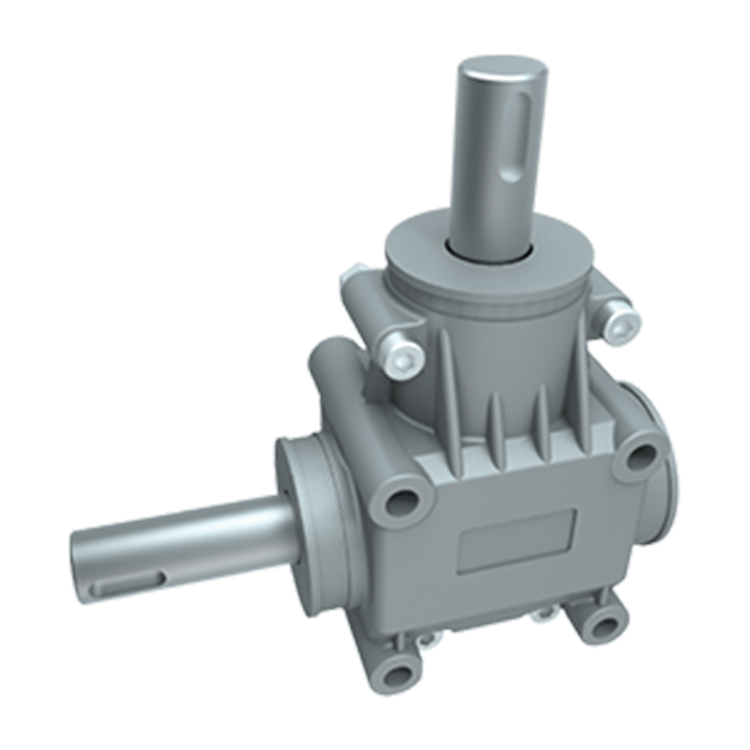

Overview

Quick Details

- Applicable Industries:

-

Production Plant, Equipment Repair Shops, Farms, Retail, gearbox for agricultural equipment equipment box for ag

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

-10000NM

- Input Speed:

-

540

- Output Speed:

-

180-1080

- Design Amount:

-

RV10

As soon as the PTO has begun to electricity the attachment, steadily improve the throttle until finally you reach the functioning pace. The common running RPM (revolutions for each moment) for a tractor mounted PTO is 540 RPM, although there are tractor versions that rev higher. Always refer to your distinct tractor product for instructions prior to 1st-time use.

- Rated Power:

-

-90KW

Source Potential

- Source Capability:

- 100000 Piece/Parts per Month

Packaging & Delivery

EPG is a leader organization in support and buying and selling functionality, in the area of Gears.

- Packaging Particulars

- wood situation

- Port

- Shanghai/Ningbo

-

Direct Time

: -

Quantity(Items) one – 1000 >1000 Est. Time(times) Our items is common exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The united states, Thailand, Pakistan, Indonesia, a lot more than sixty countries and regions.

35 To be negotiated

Online Customization

Solution Description

The GEARBOXES & DRIVESHAFTS solution line is divided into gearboxes (pace change

gears, parallel and correct angle shaft pace increasers and reducers), driveshafts and basic safety

units mainly used on agricultural equipments.

Agricultural spreader gearbox for fertilizer spreaders, Noticed benches, Belt saws,,MB-550W-15Vertical air compressor,Post gap

digger gearbox OEM-40U 1:1 ratio gearboxes

agricultural gearbox/mixer gearbox/bevel gearbox

|

Get in touch with us |

Connected product

Organization Profile

Packing & Delivery